A Tobacco Pilgrimage To El Paraiso, Honduras

By Justin Morris

It may be hard for many of you to imagine, but my life does exist outside the world of performers and artistic works and various and sundry talent all awash in the stage lights. In fact, any one of you who has known me for any stretch of time will be familiar with another long-time component of my life — fine tobacco.

To preface this grand voyage, I’ll give you a little background. When I’m not penning some rambling missive for you lovely folk out there, I spend my days working with the Halker Family that owns Lake Charles’ Cigar Club. It was there that this particular journey began — with a text message from our good friend and the Southern district sales rep for Rocky Patel Premium Cigars, Heath Hill. (He is quite likely the single nicest human in the entire industry, for the record.)

As it happened, a crew from the Carolinas was making the trip down to tour Rocky’s farms and factories. But they didn’t have the 10 people required to make the trip happen.

Our buddy Heath was tasked with filling the last four spots. In the matter of a few texts, I was bound for Central America.

Now, having taught classes on the tobacco process and on the different strains and hybrids that make up tobacco today, there’s very little of this process that I’m not familiar with. I was banking on a killer vacation, and finally, after 20 years, just getting to see all the things I’ve read and taught about. I didn’t think that I would be pulling a vast amount of knowledge from the experience. But I suppose that’s the thing about adventures … you never really know where they’re going to take you.

Sunday, Sept. 17, 4:35 am.

After driving through what I imagine to be the worst fog I’ve ever seen in SWLA, I finally found myself at Lake Charles Regional, ready to strike out. The rest of the crew was all meeting in Atlanta for the flight to Tegucigalpa. But I was solo until I met them there. Within 6 seemingly short hours of leaving Lake Charles, I was walking the tarmac in Honduras’ capital city.

The initial impression was one of surprise. Toncontín International Airport was a nice, modern and well-organized facility. The nearby mall was emblazoned with logos for Cinemark Theaters and Forever 21, and the busy roadway across the street was lined with modern brand names, like Wendy’s, Pizza Hut and Burger King (though they would likely be the largest fast food restaurants you’ve ever seen).

With my weak Spanish, I tried to explain what we were there to do. The person listening seemed very familiar with the story. With a scan of the passport, I was on my way.

Once we all got through, we walked outside to be greeted by a man holding a Rocky Patel logoed sign. This was David Gomez, an IT professional who fell in love with the industry. He has worked for Rocky for only the last 8 months. But he carries with him the knowledge of a tobacco pro.

He led us to the awaiting bus, where an ice chest full of water, soda, beer and rum, and a fully stocked humidor loaded up with Rocky’s finest Honduran-made product, awaited the excited travelers, who piled in, lit up and began the 2-hour trek into the mountains to El Paraiso.

That drive gave me my first real look at this beautiful country. The contrast of the veritable luxury of Tegucigalpa shifted into rising and falling roadways enveloped by lush green mountains that eventually began to disappear into the clouds. The pitches and valleys were covered with the facades of countless homes rising and falling with the dramatic landscape. The everyday staples of life popped up on the side of the road in a way that was somehow familiar yet also very new. Doctors, dentists, courthouses, schools … they were all there among the street vendors selling fruit or cured meat along the mountain highway that soon led us into El Paraiso, which would serve as our Honduran home for the next few days.

Once we arrived, we stopped in front of a large, nondescript, pink stucco wall whose only notable features were the electrified security wires across the top and the beautiful wooden door set into the middle.

Behind this door awaited Casa de Rocky Patel, a beautiful bed and breakfast that Rocky purchased for trips such as these. The resort feel of this place was picked up by everyone. The pool, complete with fountains and a swim-up bar; spiral staircases; rock architecture throughout the rooms and courtyard … This was plush, by any standard — much less as the free accommodations offered just by virtue of going on the trip.

Dinner (like all the meals) was delicious local fare provided by a crew of lovely local women who took great care of us during our stay. But the standout personality of the trip was our official host, whom we didn’t get to meet until after our arrival.

Her name was Maricza. I would soon learn that she was far more than our host. Maricza was, in fact, head of quality control and operations for the factory. It’s a huge task from any angle, and one that requires some next-level tobacco knowledge.

She began in quality control as one of the many, many women who work in this industry (though most work in tobacco sorting — a job that, for the most part, men aren’t even allowed to do). Over the span of four years, she got the attention of Rocky, who saw genuine tobacco talent in her.

One night, she was invited to dinner, and was the only woman seated among Rocky, the Plascencias, and more than half a dozen other world-class tobacco talents. When she succeeded at identifying a blend just by smoking it, Rocky began making her an integral part of his operation. She is so integral now, in fact, that she recently killed a very expensive original run of a blend that had been prepared for shipping because the quality was not right. Rocky trusted her, and the entire run was cut up to be used in short-filler cigars. Yeah … she was far more than just our host.

We all spent the evening smoking, drinking and getting to know each other. I was lucky to have a familiar face on the trip — a fellow by the name of Edward Taylor who used to be stationed at Ft. Polk during his Army service and whose daughter remains in the Lake City while her dad lives in North Carolina.

But it was time to get ready for Monday, when the real tobacco travels began.

Monday, Sept. 18, 9 am.

The morning started with a lovely breakfast highlighted by the most spectacular freshly made watermelon juice you could imagine. Breakfast was wonderful, but that juice may have been the food and beverage star of the trip.

Soon, we were off to Tabacos de Oriente Clasificador y Exportadora de Tabacos. This is but one of the scores of facilities owned by Plascencia in the region.

Massive pilons (aging piles) of leaf filled the industrial-sized warehouse floors that, in some places, smelled of rich tobacco, and in others smelled of pungent ammonia, depending on what point the tobacco was in the fermentation process. We saw how this seemingly endless sea of tobacco is all regularly turned and rotated by hand over the 5 to 6 years it could spend sitting there. Similarly, each massive shipping package of tobacco is sewn up by hand.

The next warehouse was one of the sorting departments on the site. It was a brightly lit room filled with tobacco. There were easily 60-80 women there, each sorting through every single leaf. Women are used all but exclusively for this task due to the fact that they have better visual acuity than men when it comes to determining variances in shade or color.

Some of the floor supervisors joined us to explain what types of tobacco were being sorted and what colorations represented higher quality or better fermented leaf. Even knowing about this in advance, I was still amazed at having the differences pointed out to me by the pros and seeing the sheer number of women working in an industry so often seen as implicitly male. It was a pretty incredible sight.

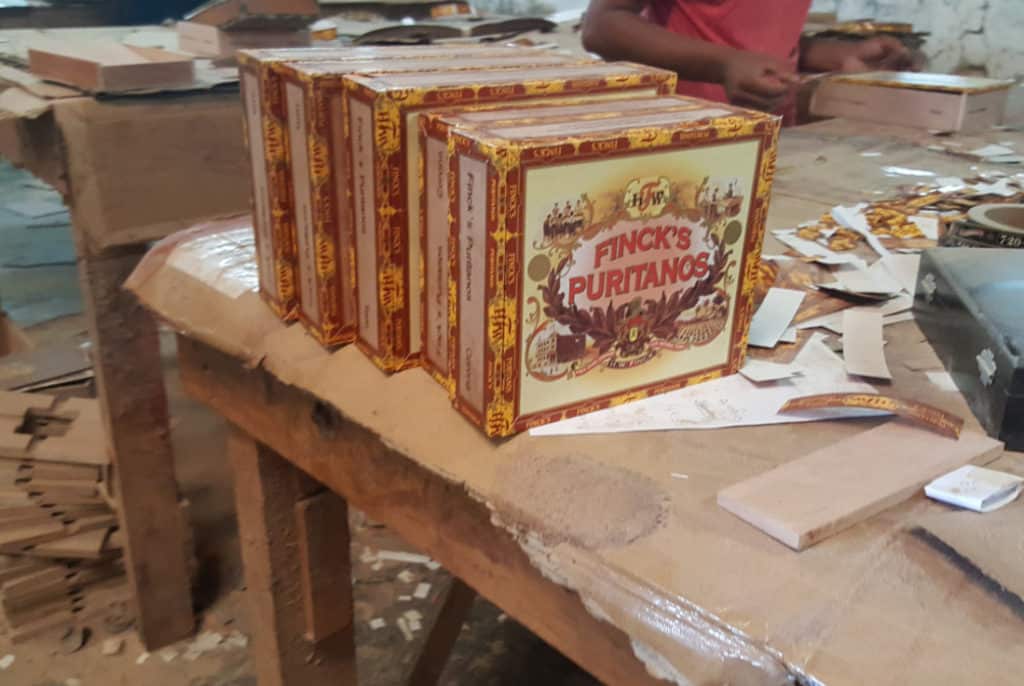

From there, we moved down the mountain to another Plascencia property, Tabacos de Oriente Farbica de Cajas. This is the box factory, where those famous, and often coveted, cigar boxes come from. Once again, the amount of handcraft seen here was remarkable. We saw workers with fine-tipped paint brushes applying each element of box labels by hand.

This small but brilliantly run operation produces some of the nicest boxes you’ve ever seen, at volume and with top-notch quality. If that much detail and work goes into the box, how much more do they put into the cigars themselves? Well, after a trip back to the Casa for lunch (with endless cigars and beverages every step of the way, mind you), we would soon find the answers.

That afternoon, we made it to the El Paraiso Factory. While the impact of seeing the immensity of the rolling floor in front of us was setting in, the roleros (rollers) and buncheros (bunchers) welcomed us with a rousing banging on their rolling tables that had everyone laughing as we made our way in. Here we saw a lot of what we had seen previously in regards to aging, fermentation, conditioning, sorting and the like. But we also got to see the entire cigar process, from bunching, to wrapping, to draw-testing, to quality control, post-roll aging, banding and boxing — all the way down to the tobacco sitting on the loading dock destined for points the world over.

Not only did we get to witness it, but we got to get involved in the process as well. We were allowed to choose five different component tobaccos. The workers would roll us each seven sticks of our own blend.

We got to watch as they made the first one to hand to us right there, fresh off the table. The rest we’d have in hand the following night at our farewell party. After the factory tour, and a short time waiting on the bus, we were back to the Casa for another night of poolside camaraderie, but joined this time by Gustavo, a Cuban-born tobacco blender and longtime Rocky Patel employee, who came to hang out, play poker and talk tobacco with all the fellas — a fun and unique ending to a long but fruitful day.

Tuesday, Sept. 19, 8 am

There’s an earlier start today, so I’m glad I skipped the poker the night before. I like the game, but it’s not exactly my wheel house. Besides, after a long nicotine- and rum-filled day, an early evening left me far fresher than some of the fellas. No watermelon juice today, sadly, but we did get fresh passion fruit juice, which is magnificent in its own right.

We were up early because we had quite the drive ahead of us. We loaded up and headed out to Jamastran, another critical region in the world of tobacco. It’s here that we finally visited the farm itself … one of them, at least. I believe it was said that Plascencia owns 13 such farms in the region.

For example: each plot of tobacco starts with 43 grams of tobacco seed. These seeds are too tiny to be measured in any other way than by weight. The example we were shown was that that volume of seed would fill, roughly, half a standard shot glass. That tiny amount of seed will, in 105 days’ time, be a 10-acre field of 6-foot tobacco plants. They’re 4-6 inches tall when they go in the field, and 60 days later they are as tall, if not taller, than anyone in our group.

The fact that I got to hold seed blew my mind. I’d heard the old adage that tobacco seed was literally worth its weight in gold. Now I understand why.

From there, we visited the aging barn — an incredible structure where tobacco is hung on poles to dry. The tobacco is loaded up and literally thrown into the air from one team to the next, moving all that leaf as high as 60-75 feet. From there, that leaf would move into the pilons that we saw in the early part of the journey.

Just outside, down the sloping path, was our field. Admittedly, it was a small one — but one that I soon gathered was actually a test field: a tobacco lab, if you will.

In this small plot, we saw beautiful tobacco, ranging from 3 1/2 to almost 7 feet high. The largest growth was on the far left and right sides of the field. We found out that each side was a different tobacco: Connecticut Broadleaf on one side and Habano (a personal favorite) on the other.

For the most part, the plants looked as gorgeous and healthy as one could imagine — all topped with a beautiful bunch of the small pink flowers, each of which can hold up to 200 of those precious little tobacco seeds. The plants had richly colored, surprisingly large, leaves.

Well, it wasn’t too long until it was time to make our way back to the Casa. An unexpected roadside stop was initiated by our Rocky Rep on board, Steven Duke, who told us of a tamale woman in this area who was a must visit. In a dusty roadside market there awaited a small restaurant and the tamale lady of such great repute. The tamales were each the size of a small po-boy bun. Cooked wrapped in leaves, filled with rice and served with a vinegary ancho chili sauce … I saw what Duke meant when he said we needed to stop. That tamale and the juice together could be well worth the cost of the plane ticket.

Our final evening at the Casa de Rocky Patel was upon us. After an epic dinner, a local band started loading in their gear to play for our farewell party. Each of us was given the rest of our cigars fresh from the factory. We all drank and smoked and partied like it was our last night in Honduras (which it was).

I was lucky enough to get Gustavo to smoke one of my blends and give me his opinion on it. I won’t go into details, but the review was good. He advised me on the one thing he’d add to finish it up. For a first-time blending effort, I’m gonna call that a win.

Wednesday, Sept. 20, 8:20 am

With the prior evening hanging heavy on me, I awoke with a start. My alarm hadn’t gone off. I looked to see whether my phone was dead, as I’d used my back-up charger the night before.

Knowing that we were probably supposed to be off to the airport soon, I scrambled to find my charger — to no avail. I finally borrowed one and powered up my phone before we left so I would at least be able to access my boarding passes for the flight home.

That in mind, I sat down to our last meal at the Casa (complete with beloved watermelon juice. One final win.) Soon after, I bade farewell to Maricza and the other lovely women and started my trip back to Tegucigalpa.

The rest of the trip was uneventful. However, the delay had put me in danger of missing my flight. As we made it to the unloading area at the airport, we discovered the Atlanta-bound crew were cutting it close, but were going to make the flight. I, however, was not quite so lucky. The next flight to Houston wouldn’t be until the following day.

Now, don’t get me wrong. The idea of staying another night certainly had its appeal. But with all the other Americans rushing off to their gate, I was ready to be in the air.

Duke swooped in and got me on the phone with their travel agent who, with a few magic keystrokes, had me booked for a Miami flight going out the following hour. That bit was the good news. The bad news was that Houston was as far as I was getting that night, and it would be midnight before that happened.

So off I ran to my new terminal, with my new airline and my new boarding passes, grabbed a new phone charger and bottle of Havana Club 7-year Cuban Rum in the duty free, and off to Miami I flew.

I spent my time at MIA both recharging my phone and trying to use it to figure out how and when I was getting from Houston to Lake Charles. I was looking at car rentals and bus tickets … But at the end of the day, family and friends made the last leg of the trip happen. My stepmother, whom I hadn’t had the chance to spend any one-on-one time with in years, picked me up and put me up for the night. She even took me by to visit my stepsister at work the next morning.

After that, she got me to Beaumont, where my roommate met me and finally got me home — about 14 hours later than I was supposed to arrive.

Now, despite all the craziness of the trip home, I can assure you that my report of this trip is nothing but a positive one. Even when the general craziness of life reared its head, I still found myself making progress and surrounded by friends new and old in a country that was as beautiful as it was educational.

It’s easy to look at the premium cigar industry as a purely indulgent pastime for those who choose to enjoy cigars. That mentality has influenced, in large part, the efforts to expand Federal regulation of the industry via the proposed plan from the FDA that has yet to be hashed out in Washington. It could wind up ensuring that the cigar I blended in Honduras will never see production.

On my trip, I gained a new appreciation for seeing some genuine good coming from this industry that, as a consumer, I enjoy, and, as a member of said industry, I love. I saw the quantity and quality of jobs the industry brings to Honduras and the other tobacco-growing countries, such as Nicaragua and the Dominican Republic. These aren’t just livelihoods, but high-quality trade jobs, not unlike what a plant operator would be in Southwest Louisiana in many instances. It’s an industry that employs young adults and old. It employs women as often as, and, in certain specifications, in preference to men. It’s an industry of craftsmanship; of hard, detailed tenacious work; of family and of love.

I’d heard that love of craft and team in every voice that spoke of working with Rocky and the Plascencias. Each enthusiast said how much he enjoyed being a part of what they’re doing in Honduras.

In many ways, I share that sentiment to a degree I never have before. I even find myself a bit envious of those who get to work much closer to the heart of the home of this leaf, and the people and places it comes from. But fear not! I won’t be winging off to live in tobacco country quite yet. I still have more missives and madness to share with you all right here at home.

For those who fancy a fine smoke on occasion, I hope the next time you have one, you’ll think of Maricza or David, and, who knows … maybe one day we’ll go down together and take a look. I plan to go back as soon as I can. I hope I’ll have some fine tobacco-loving friends to go with me.

Comments are closed.