From Sulphur Mines To Oil To Salt Brine For Industries, Sulphur Has Been One Of Most Productive Areas In The Nation

The wave of exiled Acadians settled in SWLA in the late 1700s. They were followed in the early- to mid-1800s by settlers from the Midwest who were lured to the area not just by the rich farmland, but by the promise of oil. And the region which would later be known as Sulphur was of particular interest.

In 1867, a geologist named Eugene Hilgard conducted surveys in the region for the Louisiana Petroleum and Coal Oil Co. His hundreds of samples showed there was little hope for oil in the region, however.

But Hilgard’s samples showed the strong presence of the element that would one day give Sulphur its name the area its reputation as having “the richest 50 acres in the world.”

At the time sulfur (or sulphur, as it was spelled when the discovery was made and the town named) was discovered in the area, there were no sulfur mines in the U.S.; the area in west Calcasieu Parish would be able to boast the first.

As soon as they could actually get to the sulfur deposits.

The Frasch Process

In 1870, the Calcasieu Sulphur Mining Co. was formed, and began mining for the element using the time-honored method of drilling shafts into the ground — the method used to mine coal. The method wouldn’t work in SWLA’s swampland, however. The deposits were buried hundreds of feet deep — as deep as 550 ft. — in swampland muck, limestone and quicksand, all filled with dangerous hydrogen sulfide gas. Conventional mining would continue, however, and the Calcasieu Sulphur Mining Co. change hands many times, throughout the 1870s and 1880s. Many men would lose their lives trying to access the sulfur deposits. The last attempt using this method was made in 1890, with five men killed in the attempt.

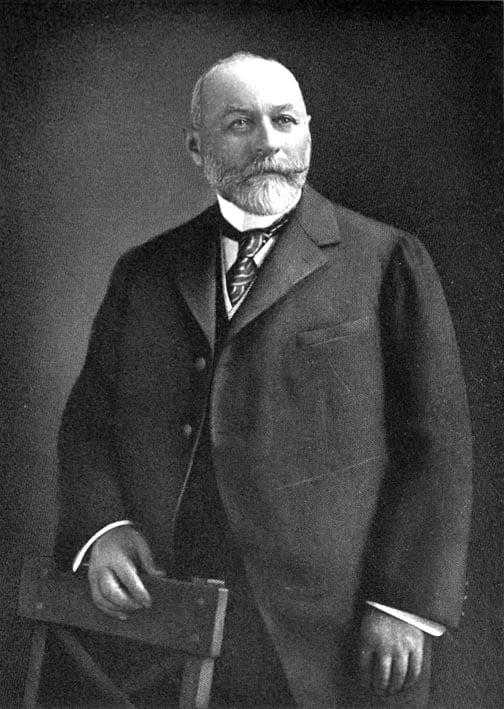

The man who would find a way to gain access to the riches of the sulfur deposits arrived in the area of Sulphur around 1890. Dr. Herman Frasch, a German chemist specializing in petroleum, came to the area as a consultant for the area oil industry. Frasch, already well known for his work with sulfur, began to devise a new way to get to the deposits lying below the soil and quicksand.

Frasch received three patents for his theory and plan in October of 1890, and took on two associates to help him develop the process: Frank Rockefeller and F.B. Squires. He then struck a 50-50 deal with the American Sulphur Co. — their sulfur deposits, his method. A new company was formed — the Union Sulphur Co.

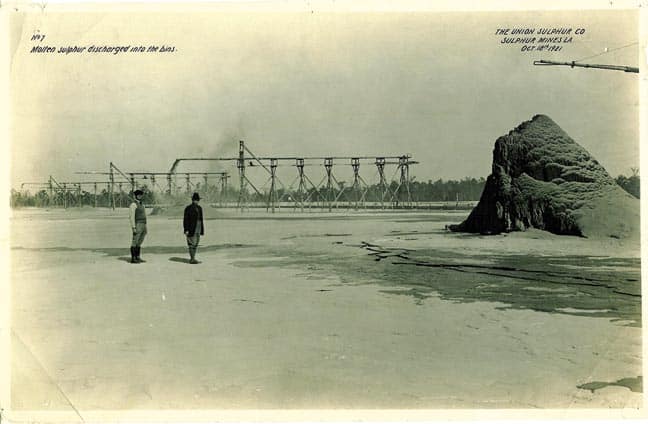

The process, still used today worldwide, involves sinking three pipes or tubes down into the deposit. In one pipe, water heated to up to 340 degrees Fahrenheit is injected into the deposit. Since sulfur melts at about 240 degrees Fahrenheit, the sulfur deposit is melted. Now in liquid form, the sulfur is forced to the surface using compressed air, and reaches the surface through the third pipe.

Frasch and his associates worked out the bugs of the new process, and on Christmas Eve, 1894, the first liquid sulfur was brought to the surface.

The Union Sulphur Co. mines would produce 23,702 tons of sulfur in 1903, and peak at 1.46 million tons in 1922. In later years, the company would produce oil, and then salt brine for use in chemical plants.

A Town Takes Shape

In the years that followed Frasch’s first successful mining, workers from Germany, Canada and the northern U.S. poured into the area to work the sulfur mines, and a railroad was constructed to get the sulfur to market.

A village had already taken shape decades earlier, with Thomas Kleinpeter laying out a village and purchasing two 40-acre tracts of land to develop. In fact, the village of Sulphur was first known as Kleinpeter Square. Kleinpeter filed his map, however, for “Sulphur City” on Jan. 27, 1900. The “City” would be dropped by the Post Office in the early 1900s, probably due to the fact that it seemed way too important a name for an area that was yet to be incorporated.

The first home in the area had already been built, in 1885, by John T. Henning, who had also opened a boarding house and built the first schoolhouse in the area, as well as its first church — a Methodist church. He also ran a general store in the area from 1893 until 1910. When he retired, he handed the reins of the store over to a young employee, who would become very influential in Calcasieu Parish in his own right — W.T. Burton.

The first business in the Sulphur area, however, a general store, was opened by Eli Perkins, a prominent Lake Charles lumberman, in 1876.

But though the beginnings of a village were already in place when Frasch’s process was first used, it was after the process was in use successfully that the area began to truly develop. Frasch built cottages for the families of workers, a boarding house for single workers, a town pavilion, and a brick schoolhouse.

The first brick schoolhouse was built in 1910, after Henning’s and Frasch’s schools were combined. The new school was named Frasch, and sat just south of the present-day Frasch Elementary.

The growth continued, and on April 17, 1914, then-Gov. Luther Hall issued a proclamation establishing Sulphur as a village. Dr. D.S. Perkins, son of Eli Perkins, was named mayor.

Since, however, the area’s population already exceeded that of a village, a petition was sent to the state asking that it be declared a town, and on June 16, 1914, it was named a town, just two months after having been declared a village.

New Industries

The Union Sulphur Mining Co. ceased its mining operations in 1924, and the last of the pine forest that had sustained Calcasieu’s timber industry had been cut. Residents and officials began looking for new industry and business opportunities for the area.

The area’s waterways would provide the answer.

Calcasieu and West Calcasieu’s waterways — both deep and shallow rivers, tributaries and channels — gave easy access to the Gulf of Mexico — and they gave rise to the huge petrochemical industry presence that sustains the area to this day.

By the late 1920s, Union Sulphur Mining had converted from sulfur to oil production. And, thanks to the area’s waterways, the area’s oil business was doing quite well, despite the looming Depression.

And the chemical plants began to move in, as well, in spite of the dire financial condition the country was in at the time. The Mathieson Alkali Works (later Olin) plant was built in Sulphur in the mid-1930s, providing many jobs for area residents.

Another reason this area didn’t experience quite as much hardship as those in other areas of the country: W.T. Burton, during this period, purchased the failing Calcasieu National Bank. He restructured it, paid its debts, and formed Calcasieu Marine National Bank. He was able to return to depositors 75 cents on the dollar — this at a time in which most banks were able to return only 10 cents per dollar. That alone helped many Calcasieu residents weather the storm of the Depression. Burton would, of course, go on to become not only an influential businessman, but a benefactor of education in the area.

During World War II, the petrochemical industry boomed in the Sulphur area. Construction began on the $72 million Cities Service plant in 1942. It would, of course, become Citgo in 1987. The plant gave rise to the town of Maplewood, and the area experienced unprecedented growth.

In the 1960s, the West Calcasieu Port Harbor and Terminal District was formed. The 190-acre port, renamed West Calcasieu Port in 2004, has played a vital role in the area’s growth.

The Next Big Boom

Sulphur’s long line of economic success continues, with the next — and unprecedented even for this area – wave of industrial expansion expected within the next two years. As it has in the past, Sulphur will experience a period of industry-related growth. And its cultural centers, restaurants, sports facilities, parks and other amenities will, as they have throughout its history, be a place new workers and new residents will be glad to call home.

Comments are closed.